I. What is the Retro-reflective Sheeting?

The retro-reflective sheeting is a kind of retro-reflective material affixed to the surface of the signs in order to enhance the identifiability of traffic signs, vehicle signs, advertisement signs, etc.

II. Classification of Retro-reflective Sheeting

The retro-reflective sheeting is usually divided into diamond grade, high-intensity grade, super engineering grade, engineering grade and economic grade retro-reflective sheeting. According to the standard GB/T 18833-2002 Retro-reflective Sheeting for Road Traffic Signs and their inverse reflection properties, the retro-reflective sheeting can be divided into five grades retro-reflective sheeting, respectively, Grade One, Grade Two, Grade Three, Grade Four and Grade Five. Additionally, according the applications of the retro-reflective sheeting, the retro-reflective sheeting stuck to the cargo type vehicles and vehicles used for the conveyance of dangerous goods are called retro-reflective sheeting for vehicle body markings (according to their inverse retro-reflection properties, they can be regarded as Class Two retro-reflective sheeting; the retro-reflective sheeting for number plates of motor vehicles are called the motor vehicle number plate retro-reflective sheeting (according to the standard GA666-2006 Retro-reflective Sheeting for Number Plates of Motor Vehicles, the inverse retro-reflection properties shall be between Grade 4-5 retro-reflective sheeting. Economic grade retro-reflective sheeting with six series, respectively, CA3100, CA3200, CA3300, CA3500, CA3600 are accordant with the technical requirements of retro-reflective sheeting with Class Five in the national standard GB/T18833-2002 Retro-reflective Sheeting for Road Traffic Signs and mainly used for signs road transport Construction, advertising and safety.

III. History of Retro-reflective Sheeting

It can be said that the development history of the road signs is also the development history of the retro-reflective sheeting .U.S. 3M Company invented the retro-reflective sheeting in 1937 and at that time the retro-reflective sheeting structure was only the exposed glass bead type; in 1948 the company developed the engineering grade retro-reflective sheeting, and developed high-intensity grade retro-reflective sheeting and diamond grade retro-reflective sheeting respectively in 1971 and 1990.

IV. Inverse Retro-reflection Principle of Retro-reflective Sheeting

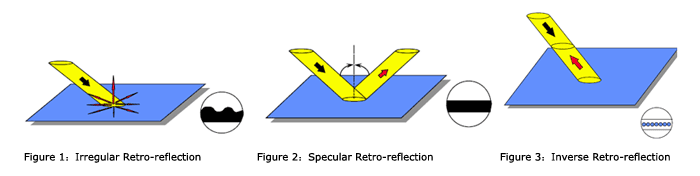

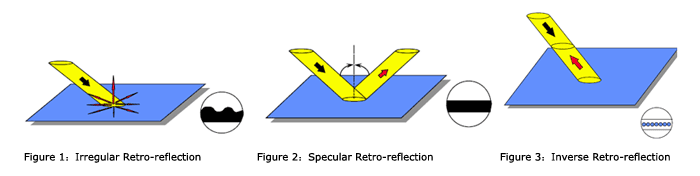

1. Category of Light Retro-reflection

Light retro-reflection can be divided into irregular retro-reflection, specular retro-reflection and inverse retro-reflection, see Figure 1 to 3.

2. What is an inverse retro-reflection?

Inverse retro-reflection is the light retro-reflected from the opposite direction near the incident light and the retro-reflection will return to the source.

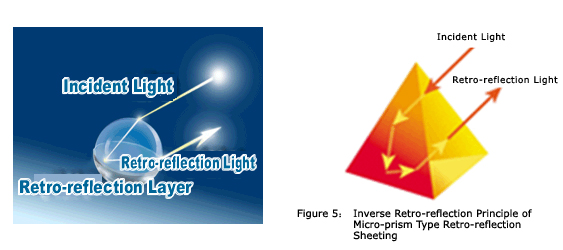

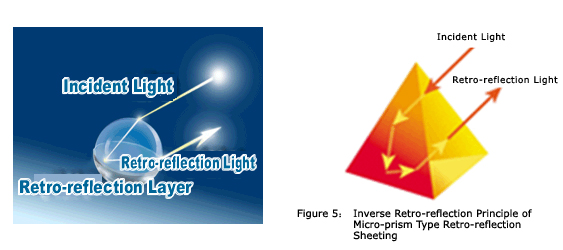

Figure 4 Inverse Retro-reflection Principle of Glass Bead Type Retro-reflective Sheeting

3. Inverse Retro-reflection Principle of Retro-reflective Sheeting

The inverse retro-reflection principle of retro-reflective sheeting consists of two types, respectively, glass bead type and micro-prism type, as shown in Figure 4 and Figure 5. High-intensity grade, super engineering grade, engineering grade, economic grade retro-reflective sheeting is glass bead type while diamond grade retro-reflective sheeting is micro-prism type.

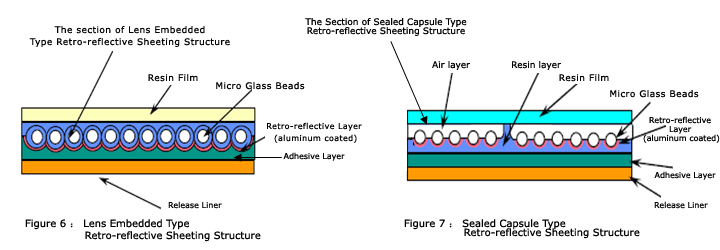

V. The Structure of Retro-reflective Sheeting

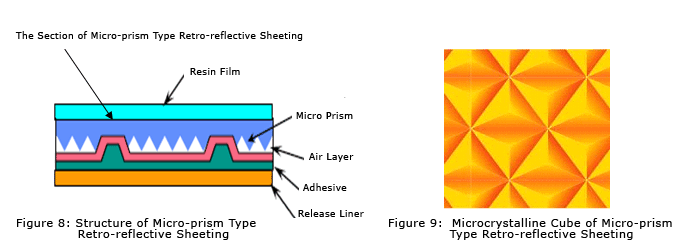

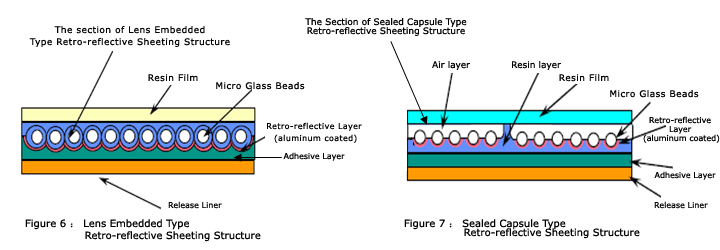

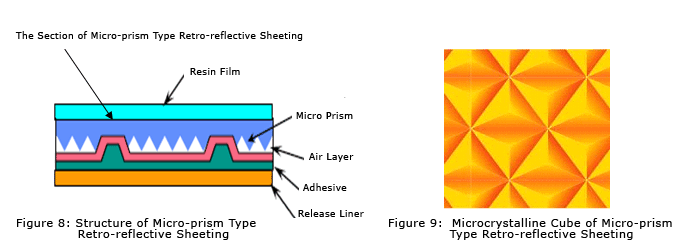

Retro-reflective sheeting structure shown in the Figure 6, 7 and 8 can be divided into three types: lens embedded type retro-reflective sheeting structure, sealed capsule type retro-reflective sheeting structure and micro-prism type retro-reflective sheeting. The structure of the super engineering grade, engineering grade and economic retro-reflective sheeting is the lens embedded type, the structure of high-intensity retro-reflective sheeting is the sealed capsule type and the structure of the diamond grade retro-reflective sheeting is the sealed capsule type. After each micro crystal cube of the diamond grade retro-reflective sheeting has been arranged and combined, there shall be 930 microcrystal cubes in one in one square centimeter material area, see Figure 9.The lower part of Microcrystalline cubic crystals being sealed , an air layer has formed in the low part of microcrystalline cubic crystals,which will make incident light form total internal retro-reflection. Accordingly they can get the most excellent retro-reflective effect without the help of the metal retro-reflective layer. Compared with the traditional engineering grade and high-intensity retro-reflective sheeting, the reflection properties of the diamond grade retro-reflective sheeting made from polycarbonate materials with high hardness and wear resistance together with microcrystalline cube technology will not fold increase, but also its wide-range properties also improve a lot

VI. Inverse Retro-reflection Property of Retro-reflective Sheeting

1.What is an inverse retro-reflection coefficient?

Inverse retro-reflection coefficient =Luminous Intensity Coefficient of the Flat Inverse Retro-reflection Surface/Area of Flat Inverse Retro-reflection Surface

R′= R / A

In the formula:

R′—Inverse Retro-reflection Coefficient (cd/1x-1/m-2)

R—Luminous Intensity coefficient (cd/lx-1)

A—Area of Specimen Surface,m2

2.Inverse Retro-reflection Properties of Frequently-used Retro-reflective Sheeting

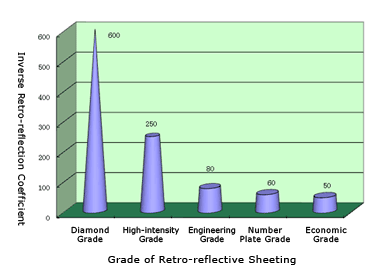

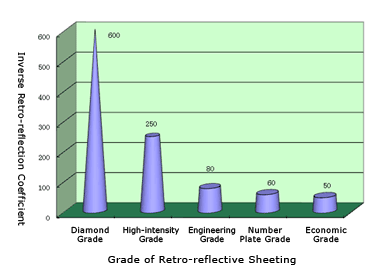

When the observation angle 0.2 °and incidence angle is -4°, the inverse retro-reflection coefficients (cd/1x-1/m-2) of the silvery white diamond grade, high-intensity grade, engineering grade, vehicle plate grade (motor vehicle license plates) and economic grade retro-reflective sheeting are shown in Figure 10.

Figure 10 Inverse Retro-reflection Property Comparison of Frequently-used Retro-reflective Sheeting

VII. Other Property Requirements of Retro-reflective Sheeting

According to GB / T 18833-2002 Retro-reflective Sheeting for Road Traffic Signs, Class 1-5 retro-reflective sheeting has requirements not only for inverse reflection properties, but also for chrominance properties, adhesion properties, the removeable properties of release paper, weatherability, salt spray corrosion resistance, solvent resistance, shock resistance, bending resistance, high and low temperature resistance, shrinkage, tensile properties and adhesion between ink and reflective films. Water resistance is also requirement for retro-reflective markings of carriage and number plates for motor vehicles. In addition, the retro-reflective sheeting for number plates of motor vehicles also needs to test the embossing resistance, wash-resistant property and anti-sandstorm resistance.

VIII. The Application of Retro-reflective Sheeting

Retro-reflective sheeting is mainly used for guiding signs, direction board, outline sign, protruding signs, traffic cones, crash barriers barrels, safety islands for various roads and railways, and mine and airport safety signs, place name plates, number plates for vehicles, safety signs for residential quarters, construction signs, billboards, stage scenery, trademarks, etc. In the daytime, the bright colors of the retro-reflective sheeting plays a clear warning role, at night or under poor lighting conditions, the bright retro-reflection effect can enhance people’s identification ability to see the target and raise the alert to avoid accidents, reduce casualties and minimize the economic losses. Retro-reflective sheeting has become an indispensable road traffic safety guard and has clear social benefits.

The application of engineering grade, high-intensity grade and diamond grade retro-reflective sheeting are described as follows:

1. Engineering Grade Retro-reflective Sheeting Engineering grade retro-reflective sheeting is applicable to the traffic signs for general roads, namely, usual Class-A, Class-B, Class-C, Class-D roads and signs for the temporary use. Engineering grade retro-reflective sheeting is often used for guide signs, prohibition signs, warning signs, indicative signs and general advertising signs. With the screen printing technology, various patterns can be printed with the same ink. The lifespan of the retro-reflective sheeting is generally 3-7 years.

2.High-intensity Grade Retro-reflective Sheeting

High-intensity grade retro-reflective sheeting has been successfully used to make traffic signs. Even if the signs in the larger perspective as well as bright areas, high-intensity grade retro-reflective sheeting is able to make the signs clearly visible to foretell drivers dangerous road conditions ahead.

High-intensity grade retro-reflective sheeting is applicable to the traffic signs for general roads, namely, usual Class-A, Class-B, Class-C, Class-D roads and signs for the temporary use. High-intensity grade retro-reflective sheeting is often used for guide signs, prohibition signs, warning signs, indicative signs and general advertising signs. The lifespan of the retro-reflective sheeting is generally 10 years. In normal use, after 10 years the retention value of inverse retro-reflection coefficient shall be at least 80% of the initial inverse retro-reflection coefficient.

2.Diamond Grade Retro-reflective Sheeting

Diamond grade retro-reflective sheeting is applicable to the traffic signs for high-grade highways and urban roads. Diamond grade retro-reflective sheeting is often used for guide signs, prohibition signs, warning signs, indicative signs and general advertising signs. With the screen printing technology, various patterns can be printed with the same ink. The lifespan of the retro-reflective sheeting is generally 3-7 years. In normal use, after 10 years the retention value of inverse retro-reflection coefficient shall be at least 80% of the initial inverse retro-reflection coefficient.

IX. Production Technology of China-made Retro-reflective Sheeting

Over the past decade, retro-reflective sheeting production technology in China has developed rapidly and China has proprietary intellectual property rights for a number of reflective materials; economic grade, engineering grade and high-intensity grade retro-reflective sheeting has formed product series and retro-reflective sheeting for number plates of motor vehicles and retro-reflective markings of carriage also have begun the mass production; retro-reflective sheeting made in China not only replaces the imports, but also sells to overseas countries.

Three major technical difficulties for production of retro-reflective sheeting are materials, equipments and technology.

The main materials of retro-reflective sheeting, namely, resins, pigments and micro glass beads, make crucial influence on the properties of retro-reflective sheeting. Among them, the resin shall have superior coating, adhesion, match, durability, etc. and resin in surface layer and focusing layer shall have superior light-admitting quality. For pigments, they have not only bright colors and stable hue, but also have high transparency and compatibility with resin. Micro glass beads are illustrated in Figure 11, particle sizes are only 35 ~ 90μm, which are even much thinner than human hair; round particle sizes, low translucence rate, high refraction rate and particle size distribution rate are required.

Domestic production equipments for retro-reflective sheeting mostly make up production lines and production equipments can be contacted with each other to form a group or production line operation according to technological requirements. Coating and laminating production lines both adopt frequency conversion, synchronization, correction and constant tension control; oven temperature can be controlled precisely through region divisions; coating and winding stations have basically achieved constant temperature operations.

The domestic technological level of retro-reflective sheeting is basically close to the international level. In particular it should be noted that some enterprises just adopt the simple bead plant method to solve the problems of single layer’s coplanarity and even distribution. However, at present domestic diamond grade retro-reflective sheeting are still in development and trial production stage; the share of the China-made high-intensity grade retro-reflective sheeting on the highways is still relatively low; independent research and development capacity, production techniques and product quality of the China-made remain to be further improved.